The working principle of a reducer is based on the transmission of power and motion, converting high-speed rotational motion input into low-speed rotational motion output while increasing torque. Specifically, the working principle and differences in the principles of different types of reducers are as follows:

Basic working principle of gearbox

When the power source (such as a motor) drives the input shaft of the gearbox to rotate, the gears on the input shaft mesh with other gears for transmission. According to the basic laws of gear transmission, when a small gear drives a large gear, the speed of the large gear will be lower than that of the small gear due to its large number of teeth and diameter, while the torque will correspondingly increase

Power=torque x speed. When the input power remains constant, a decrease in speed will inevitably lead to an increase in torque

The reduction ratio is the ratio of the input shaft speed to the output shaft speed, determined by the ratio of the number of teeth of the meshing gears

.

The differences in the principles of different types of reducers

gear reducer

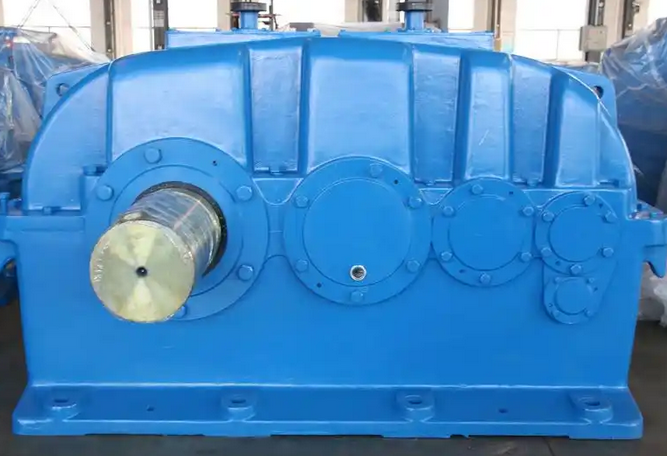

Parallel axis gear reducer: The input shaft and output shaft are arranged in parallel, using cylindrical gears with different numbers of teeth to mesh with each other and transmit power. Power is transmitted from the small gear on the input shaft to the large gear on the output shaft, achieving deceleration and torque increase. It is commonly used in situations where space requirements are relatively relaxed.

Vertical axis gear reducer: The input shaft and output shaft are perpendicular to each other, and power transmission is achieved through bevel gears, etc. It is suitable for environments with limited installation length.

Planetary gearbox: composed of sun gear, planetary gear, and inner ring gear. When the ring gear is fixed, the sun gear is active, and the planet carrier is passive, the sun gear drives the planet gears to rotate. The planet gears not only revolve around the sun gear but also rotate on their own. The planet gears mesh with the inner ring gear, reducing the output speed of the planet carrier and increasing the torque. The planetary gearbox has a compact structure and high transmission efficiency, usually reaching over 90%.

Worm gear reducer: composed of a worm and a worm wheel, the worm wheel is in a spiral shape, and the worm wheel is a cylindrical gear that meshes with the worm. The helix angle of the worm and the number of teeth of the worm wheel are relatively large, so that when the worm rotates once, the worm wheel only rotates a small angle, thereby achieving a large transmission ratio reduction. It has reverse self-locking function, and the input shaft and output shaft are not on the same axis or plane. The transmission is smooth without obvious impact and vibration, but the transmission efficiency is relatively low.

Cycloid pinwheel reducer: It adopts the planetary transmission principle of cycloidal pinwheel meshing. The cycloidal gear swings under the eccentric action of the input shaft and meshes with the pinwheel on the pinwheel housing to achieve deceleration. The cycloidal gear rotates at an angle less than one revolution per revolution, achieving the purpose of deceleration. It has the advantages of high transmission ratio, smooth transmission, low noise, and high efficiency.

Name: Hu Bo

phone:

Whatsapp:+8618881888393

Email:supplychainalliance.cn@gmail.com

Add:No. 10 Xiyuan Road, Hangzhou City, Zhejiang Province, China