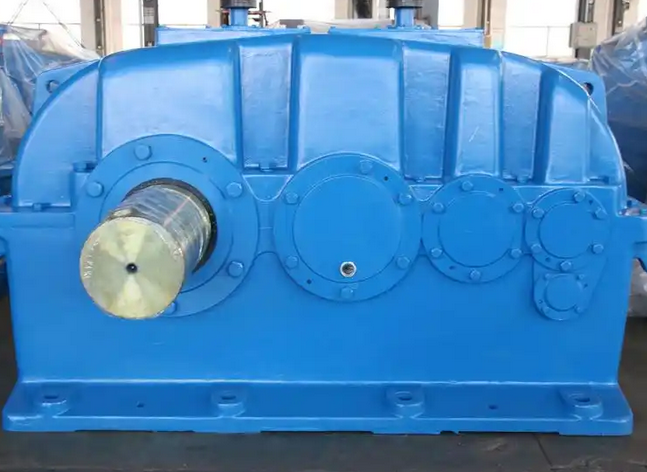

Choosing a ZFY hard tooth surface cylindrical gear reducer that suits your needs requires comprehensive consideration of multiple factors. The following are specific points:

Clarify the working condition requirements

Torque requirement: Accurately calculate the resistance torque that the equipment needs to overcome during operation. For example, in the application of conveyor belts, the required torque should be calculated based on the length of the conveyor belt, the weight of the loaded goods, the operating speed, etc., to ensure that the selected reducer can provide sufficient output torque to ensure smooth and efficient operation of the equipment.

Speed requirement: Determine the required output speed based on the actual application scenario. Automated production line equipment typically requires precise and stable low-speed output to ensure machining accuracy; Ventilation equipment requires relatively high rotational speed output to achieve sufficient air circulation, and a suitable speed ratio reducer is selected accordingly.

Load characteristics: Analyze the nature of the load. If the load is stable, such as a uniformly rotating mixing equipment, the selection can be relatively conventional; If there is a significant impact on the load, such as stamping machines and other equipment, it is necessary to choose a reducer model with strong impact resistance and sturdy structure to ensure that it can work normally under high load impact and extend its service life.

Work environment: Consider factors such as temperature, humidity, dust, and corrosiveness in the work environment. If the working environment temperature is below 0 ℃, the lubricating oil needs to be preheated before starting; In environments with high temperature, humidity, high dust or corrosive media, it is necessary to choose gearboxes with corresponding protection levels and anti-corrosion performance.

Determine technical parameters

Transmission ratio: Calculate the transmission ratio based on the input speed and the required output speed, select a reducer that can meet the requirements of the transmission ratio, and also consider the transmission stages of the reducer. ZFY is a four stage cylindrical gear reducer that can provide a large range of transmission ratios.

Rated power: The rated power of the selected reducer should be greater than or equal to the power required by the equipment to ensure that the reducer can continue to operate stably under rated conditions and avoid overload damage.

Protection level: Select the appropriate level of protection for the gearbox based on the dust, moisture, and other conditions in the working environment. For example, in dusty and humid environments, it is necessary to choose a gearbox with a higher protection level of IP54 or IP65.

Consider installation and maintenance

Installation method: Choose the appropriate installation method based on the structure and spatial layout of the equipment, such as horizontal installation, vertical installation, flange installation, or foot installation. Ensure that the gearbox is easy to install and securely connected to other equipment.

Convenience of maintenance: Choose a gearbox that is easy to maintain, such as one with good oil filling, draining, and inspection hole design, which facilitates regular inspection of lubricating oil quantity, oil quality, and gear wear, as well as cleaning and maintenance operations.

Name: Hu Bo

phone:

Whatsapp:+8618881888393

Email:supplychainalliance.cn@gmail.com

Add:No. 10 Xiyuan Road, Hangzhou City, Zhejiang Province, China