When using a servo motor with a worm gear reducer, how to match it properly

When choosing servo motors and worm gear reducers, it is necessary to select servo motors and reducers of corresponding capacity according to the workload size and motion trajectory requirements to ensure efficient power transmission and motion control.

Specifically, you can refer to the following steps for matching:

Firstly, it is necessary to determine the size of the workload and the requirements for the motion trajectory, in order to select suitable servo motors and reducers. Generally speaking, the appropriate reduction ratio and output torque can be selected based on the requirements of the motion control system and practical application scenarios to ensure that they can meet actual needs.

Secondly, it is necessary to consider the control modes of servo motors, which usually include position control mode, speed control mode, and force control mode. According to specific application requirements, corresponding control modes can be selected and adjusted accordingly to achieve optimal motion stability and accuracy.

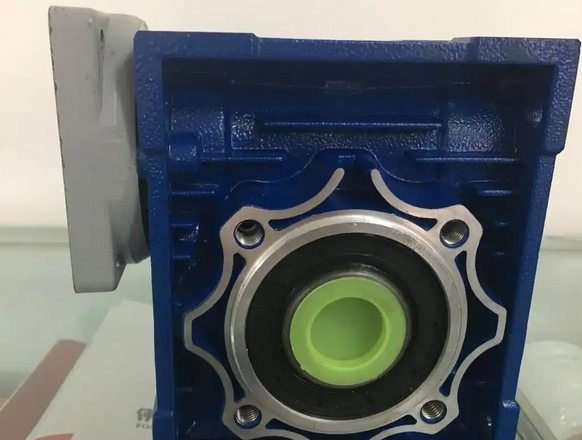

Finally, it is necessary to accurately install the servo motor and reducer, and connect them together using a suitable coupling. During the debugging process, it is necessary to adjust the servo motor and reducer according to the feedback signal of the motion control system to ensure their stability and accuracy, and conduct long-term load testing to test their durability and performance.

In short, when choosing servo motors and worm gear reducers, it is necessary to comprehensively consider the actual application requirements and specific installation and debugging requirements, and make reasonable combinations to ensure efficient power transmission and motion control.

Name: Hu Bo

phone:

Whatsapp:+8618881888393

Email:supplychainalliance.cn@gmail.com

Add:No. 10 Xiyuan Road, Hangzhou City, Zhejiang Province, China